The Mathematics of Reinforced Concrete Design in Construction

What Is Reinforced Concrete?

Reinforced concrete is a building material that combines two essential components: concrete and steel reinforcement bars (commonly called rebar). Concrete on its own is very strong when it comes to handling pressure (called compression), but it is weak when stretched or bent (called tension). Steel, on the other hand, is excellent at handling tension but not as strong under compression. When you put these two materials together, you get a strong and reliable material that can resist both forces — and that’s what we call reinforced concrete.

This combination works so well because concrete sticks tightly to steel, forming a solid bond that lasts for decades. When loads or forces are applied to a building, the concrete handles the weight, while the steel absorbs any pulling or bending stress. This teamwork between the two materials allows engineers and builders to design structures that are safe, stable, and long-lasting.

Reinforced concrete can be poured into almost any shape, making it a flexible material for building floors, walls, columns, beams, bridges, and many other types of construction. Once it hardens and cures properly, it becomes incredibly tough and ready to support heavy structures for many years.

Why Is It Used in Construction?

Reinforced concrete is one of the most commonly used materials in construction today — and for good reasons. First and foremost, it provides excellent strength and durability. Structures made with reinforced concrete can carry heavy loads, resist harsh weather, and stand up to natural disasters like earthquakes, storms, and even fires. That’s why you often see it used in bridges, high-rise buildings, parking garages, dams, and foundations.

Another reason it's so popular is that it's cost-effective. The materials needed (cement, sand, gravel, and steel) are usually affordable and easy to find in most parts of the world. Plus, reinforced concrete structures require less maintenance compared to other materials like wood or plain steel, which can rot or rust over time.

Reinforced concrete is also flexible in design. It can be molded into almost any shape before it sets, giving architects and engineers the freedom to create everything from simple homes to complex bridges or artistic buildings. It also provides great sound insulation and thermal resistance, making it suitable for residential, commercial, and industrial use.

Understanding the Basics

Concrete vs. Reinforced Concrete

Concrete is a mixture of cement, water, sand, and gravel or crushed stone. It hardens over time and becomes a rock-like material that is very strong in compression — meaning it can handle a lot of weight pushing down on it. This makes concrete a great choice for foundations, pavements, and floors.

However, plain concrete has a weakness: it doesn't perform well under tension, which is the force that tries to pull or bend it. When a structure bends, such as under the weight of people, cars, or wind, plain concrete can crack or break.

This is where reinforced concrete comes in. It has steel bars (rebar) embedded inside the concrete before it hardens. These steel bars are placed in the areas where tension is expected, helping the concrete resist cracking and bending. The result is a much stronger and more flexible material that can handle both pressure and stretching forces — making it ideal for most building projects.

The Role of Steel in Reinforcement

Steel plays a critical role in reinforcing concrete. Unlike concrete, steel is extremely strong when pulled or bent. When you embed steel bars inside concrete, they take on the job of resisting tension while the concrete itself handles compression. This partnership makes structures safer, more stable, and more durable.

Another reason steel is a great match for concrete is because the two materials expand and contract at nearly the same rate with changes in temperature. This means they work well together in all kinds of weather without separating or weakening over time.

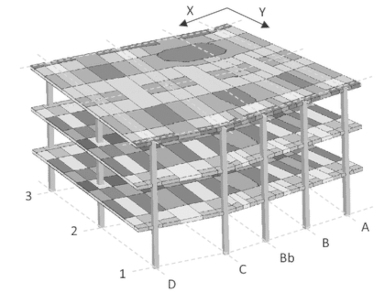

In reinforced concrete, steel is usually arranged in a grid-like pattern or in specific areas where tension is expected, such as the bottom of beams or the middle of slabs. These steel bars are carefully calculated and placed by engineers to ensure the structure can handle expected loads and forces.

Without steel reinforcement, many modern structures — like bridges, high-rise buildings, and even simple balconies — would not be able to stand up to the stresses they face every day. Steel reinforcement turns basic concrete into a high-performance material suitable for safe, strong, and long-lasting construction.

Why Math Matters in Concrete Design

How Math Ensures Safety and Stability

Math is at the heart of every safe and stable building made with reinforced concrete. Before a single drop of concrete is poured, engineers use math to calculate how much weight a structure must support, how thick the concrete should be, and how much steel reinforcement is needed.

These calculations are not just about making things strong — they are about making things safe. If the math is wrong, a building could crack, tilt, or even collapse. That’s why construction professionals rely on formulas and measurements to determine the right proportions of concrete mix, the spacing and thickness of steel bars, and the ability of a structure to handle loads like people, furniture, vehicles, wind, or even earthquakes.

For example, math helps answer questions like: – How thick should a concrete slab be for a two-story house? – How much steel do we need in a beam to support a bridge? – Will the structure bend or crack under heavy rain or snow?

By getting the numbers right, math helps ensure that buildings remain safe and strong for many years to come.

Everyday Examples of Concrete Math

You may not realize it, but math in concrete design shows up in many everyday construction decisions. Here are a few simple examples:

- Mixing Concrete: To make strong concrete, workers follow a specific ratio — for example, 1 part cement, 2 parts sand, and 4 parts gravel. Too much water or too little cement can weaken the mix.

- Measuring Reinforcement: If you're pouring a concrete patio, you might calculate that you need one steel bar every 12 inches across the surface. That spacing is based on math to support weight and resist cracks.

- Volume Calculations: Want to pour a concrete driveway? You’ll need to calculate the length × width × thickness to know how many cubic meters or cubic feet of concrete to order — and avoid running out or overpaying.

- Load Capacity: Engineers calculate how much weight a column or beam can hold to make sure it doesn’t fail under pressure. This protects people and property.

Even though you may not see the math on the surface, it’s working quietly behind every wall, floor, and ceiling — helping buildings stand tall, strong, and secure.

Loads and Forces Explained Simply

What Are Loads in a Building?

In construction, a "load" is any force or weight that a building must support. Think of it like the pressure that pushes down, pulls, or pushes against parts of a structure. These loads come from different sources, and understanding them is key to designing buildings that are safe and strong.

There are three main types of loads:

- Dead Loads: These are the permanent parts of a building — like walls, floors, ceilings, and the roof. They don’t change over time and are always present.

- Live Loads: These are the movable or changing weights — such as people, furniture, cars in a parking garage, or even snow on a roof. They vary throughout the life of the building.

- Environmental Loads: These come from nature — like wind, rain, earthquakes, or temperature changes. They can apply extra pressure or movement to a structure.

Every time someone walks across a floor or a strong wind hits the side of a building, that force is considered a load — and the structure must be ready to handle it.

How Concrete Handles Pressure and Weight

Concrete is very good at handling pressure, also known as compression. For example, if you build a tall column and put a heavy weight on top, the concrete can support that weight without crumbling — this is what makes it perfect for foundations, pillars, and walls.

However, concrete alone isn’t as good at handling other forces — like bending, stretching, or twisting. That’s why we use steel reinforcement inside the concrete. The steel helps manage the parts of the structure that experience pulling or bending, while the concrete supports the pushing forces.

Think of it like this: concrete is great at holding things up, but when forces try to pull it apart or bend it, steel steps in to help. Together, they create a balanced and reliable material that can safely support a building through all kinds of loads — from heavy furniture to strong winds and earthquakes.

This careful balance is made possible by math, engineering, and a deep understanding of how buildings respond to the world around them. And it all starts with knowing what kinds of loads a structure will face.

Thickness, Spacing, and Quantity

How Engineers Decide Concrete Thickness

The thickness of concrete in a building depends on how much weight it needs to support and where it’s being used. For example, the floor of a small home doesn’t need to be as thick as the foundation of a multi-story building or a busy parking lot.

Engineers use calculations to determine the right thickness based on:

- Type of structure: Is it a house, a bridge, or a warehouse?

- Load requirements: How much weight will the concrete support?

- Soil conditions: Is the ground underneath soft or firm?

- Reinforcement: How much steel will be added to help support the load?

For example, a residential floor slab might be 4 inches (about 10 cm) thick, while an industrial slab might need to be 6–8 inches (15–20 cm) or more. Getting this measurement right is important to avoid cracks or failures over time.

Why Steel Bars Need Proper Spacing

Steel bars, or rebar, are placed inside concrete to make it stronger — but their placement isn’t random. The spacing between steel bars is carefully planned to ensure the concrete can handle both compression and tension forces evenly across the structure.

If steel bars are placed too far apart, parts of the concrete may become weak and start to crack under stress. If they’re too close together, it can make the concrete harder to pour and may not allow it to bond well with the steel. Both situations can reduce the strength and life of the structure.

Proper spacing also depends on:

- Load and stress areas: Heavier loads usually need more closely spaced steel bars.

- Concrete cover: The steel bars need to be protected from moisture and rust, so they should be placed at the right depth inside the concrete.

- Type of project: A thin concrete slab may require smaller bars with tighter spacing, while thick beams or columns use larger bars with wider spacing.

The Importance of Ratios and Strength

Water-Cement Ratio in Simple Terms

The water-cement ratio is one of the most important factors in making strong concrete. It’s a simple concept: it compares the amount of water to the amount of cement in a concrete mix. For example, if you use 50 liters of water with 100 kilograms of cement, the water-cement ratio is 0.5.

This ratio controls how strong and durable the concrete will be. Here's why:

- Too much water: Makes the concrete easier to pour, but also makes it weaker and more likely to crack or wear out over time.

- Too little water: Makes the mix dry and hard to work with, which can lead to poor bonding and uneven results.

Engineers aim for a balanced ratio — enough water to make the concrete workable, but not so much that it weakens the final product. A common ratio for strong concrete is between 0.4 and 0.6, depending on the project.

Getting this ratio right is key to building solid, long-lasting structures.

Concrete Grades and What They Mean

Concrete grades are used to describe the strength of concrete. They tell you how much pressure the concrete can handle once it’s fully hardened — usually measured after 28 days. The grade is shown as a number, like M20 or C25, where the number stands for the strength in megapascals (MPa).

Here are a few common grades and their uses:

- M10 or C10: Used for pathways or non-structural work.

- M15 or C15: Suitable for simple floors or slabs with light loads.

- M20 or C20: Commonly used in residential construction for beams, columns, and slabs.

- M25 or higher: Used in commercial buildings, bridges, or areas with heavy load demands.

The higher the grade, the stronger the concrete. Choosing the right grade ensures the structure can safely carry the expected loads without cracking or failing over time.

How to Read Simple Concrete Plans

Decoding the Numbers and Symbols

Concrete plans (also called structural drawings) are like blueprints that show how a building or structure should be built using reinforced concrete. At first glance, they may seem full of confusing numbers, lines, and symbols — but with a little guidance, you can understand the basics.

Here are a few common elements you’ll see:

- Dimensions: Numbers like “200 mm” or “8 in” show the size of slabs, beams, or columns.

- Rebar symbols: A note like “T12 @ 200 mm c/c” means 12 mm diameter steel bars placed every 200 mm center-to-center.

- Concrete grade: You might see labels like “M20” or “C25” indicating the strength of the concrete to be used.

- Section views: Cross-sectional drawings help you see what the structure looks like from the side — showing thickness, depth, and where the steel bars go.

- Arrows and labels: These point to key areas and explain what each part of the plan represents, such as footings, slabs, beams, or walls.

Learning to recognize these basic notations helps you better understand what’s being built and how it's reinforced to be safe and durable.

What to Look for as a Homeowner or Client

Even if you're not an engineer, there are a few things you can check on a concrete plan to stay informed and confident about your project:

- Structural elements: Check that all major parts of the structure are clearly labeled — such as foundations, columns, beams, and slabs.

- Concrete thickness: Make sure the concrete is thick enough for its purpose — for example, 4 inches (100 mm) is typical for home floors, while driveways or commercial floors may need more.

- Rebar placement: Look at how often steel bars are spaced (e.g., every 150 mm or 200 mm). Closer spacing usually means greater strength.

- Load-bearing areas: Identify where the heavy loads will be, like under walls or columns, and ensure those areas have stronger reinforcement.

- Concrete grade: Confirm that the concrete strength (e.g., M20 or higher) matches the use of the structure — especially for floors, beams, or any area that carries weight.

If anything looks unclear, don’t hesitate to ask the engineer or contractor to explain it in simple terms. As a homeowner or client, understanding the basics of a concrete plan can help you feel more involved, avoid mistakes, and ensure the work meets proper standards.

Cost and Material Estimates

How Math Helps Estimate Concrete Needed

Before any concrete is mixed or poured, it’s important to estimate how much material will be needed. This helps avoid running short during the project — or ordering too much and wasting money. Thankfully, some basic math can help figure it out.

To estimate concrete, the most common formula is:

Volume = Length × Width × Thickness

Let’s say you’re pouring a concrete slab for a patio that is 4 meters long, 3 meters wide, and 0.1 meters thick:

- Volume = 4 × 3 × 0.1 = 1.2 cubic meters

This tells you how much wet concrete you need. From there, you can calculate how many bags of cement, how much sand, gravel, and water are needed based on standard mix ratios. Contractors often add 5–10% extra to account for spills or uneven surfaces.

Math also helps estimate the cost of materials. Once you know how much of each material you need, you can multiply by the local price per unit to get a total cost estimate. This makes budgeting easier and helps avoid surprises.

Avoiding Waste and Overuse

Ordering too much concrete leads to waste — which costs money and creates disposal problems. On the other hand, ordering too little can delay the project and may result in weak joints between separate pours.

To avoid waste and overuse:

- Measure carefully: Double-check the length, width, and thickness of the area to be poured.

- Use accurate mix ratios: Don’t guess the amounts of cement, sand, or water. Use standard formulas for reliable strength.

- Account for shapes: For irregular areas, break them into smaller rectangular or circular sections to calculate the volume more accurately.

- Consult a professional: If in doubt, ask an engineer or contractor to help with your estimate — especially for large or complex projects.

Common Mistakes and Misunderstandings

Myths About Concrete Strength

Many people believe concrete is always strong no matter how it’s mixed or poured — but that’s not true. There are several common myths about concrete that can lead to problems if not corrected:

- Myth 1: “The more cement, the stronger the concrete.”

Adding too much cement can actually weaken concrete. It may crack more easily and shrink too much as it dries. Balance is key — the right mix of cement, sand, gravel, and water creates the best strength. - Myth 2: “Concrete becomes strong immediately after pouring.”

Concrete takes time to gain strength. It usually reaches its full strength after 28 days. That’s why it’s important not to overload or build on it too soon. - Myth 3: “Concrete doesn’t need reinforcement.”

Plain concrete can crack under tension or bending. Steel reinforcement is essential in many structures — even small slabs — to prevent failure over time.

When Poor Math Leads to Structural Issues

Concrete construction relies heavily on accurate math. If the numbers are wrong, the results can be dangerous — or very expensive to fix. Here are a few examples of how poor math can lead to serious issues:

- Incorrect volume estimates: If the volume of concrete is underestimated, the project may run out of material before completion — leading to rushed second pours or weak joints.

- Wrong concrete thickness: Using a slab that’s too thin can result in cracks or failure under weight. Overbuilding (too thick) wastes money and materials.

- Poor rebar spacing: If steel bars are placed too far apart or in the wrong position, the concrete may not handle tension properly and could crack or collapse under stress.

- Ignoring load calculations: A beam or column not designed to support the real load (weight) may become a risk for structural failure.

Even small math errors in concrete design — like using the wrong unit or misplacing a decimal — can lead to unsafe buildings, legal issues, and extra costs. That’s why experienced engineers and builders always double-check their calculations and follow building standards closely.

For homeowners and clients, understanding these risks helps you ask the right questions and make informed decisions — ensuring your project is both safe and successful.

Real-Life Applications

How It All Comes Together in Homes, Roads, and Buildings

Reinforced concrete is used almost everywhere around us. From small homes to massive skyscrapers, its strength, durability, and flexibility make it one of the most trusted materials in construction. Here's how everything you've learned — from thickness and ratios to steel reinforcement — comes together in real projects:

- Homes: In residential buildings, reinforced concrete is used for foundations, floors, and structural columns. A strong foundation prevents settling or cracking over time, especially in areas with shifting soil or heavy rain.

- Roads and Highways: Concrete roads are designed to handle the weight of thousands of vehicles every day. Engineers calculate the correct thickness and spacing of steel mesh to prevent cracks and potholes from forming.

- Commercial Buildings: Offices, schools, hospitals, and malls all rely on reinforced concrete for their structure. Beams and columns made with the right amount of steel and concrete keep these buildings strong and safe, even during heavy use or natural disasters.

- Bridges and Infrastructure: Bridges are exposed to extreme loads and weather conditions. Reinforced concrete allows them to stay strong for decades, especially when designed with proper load calculations and protective coatings for the steel inside.

Case Studies and Simple Success Stories

Here are a few simple examples that show how reinforced concrete math and design make a real difference:

- Homeowner Avoids Future Repairs: A homeowner in a flood-prone area followed an engineer’s plan to use reinforced concrete for the basement walls and floor. Thanks to proper thickness, waterproofing, and steel reinforcement, the home has stayed dry and crack-free for over 10 years.

- Small Business Builds a Long-Lasting Driveway: A local shop owner used reinforced concrete for their delivery area. By choosing the correct concrete grade and spacing rebar every 12 inches, the driveway now holds up against heavy truck traffic without cracking.

- Community Bridge Built to Last: In a rural town, a small bridge was built using carefully designed reinforced concrete. Thanks to proper load calculations and well-placed rebar, it has withstood floods and daily traffic for over 15 years with minimal maintenance.

These real-life applications show that when reinforced concrete is designed and built with the right math and planning, it creates strong, safe, and long-lasting results. Whether it’s a simple patio or a city bridge, good design makes all the difference.

Frequently Asked Questions

Simple Answers to Common Concerns

- Do I need to worry about concrete math if I’m not the builder?

Not directly — but understanding the basics helps you ask smart questions and make sure your project is done right. - Can I pour concrete without using steel reinforcement?

In some small jobs like garden paths, maybe. But for anything that carries weight — like floors, walls, or beams — steel reinforcement is essential for safety and durability. - How can I tell if my contractor is using the right concrete mix?

Ask for the mix details and check if they mention the concrete grade (like M20 or C25) and water-cement ratio. You can also ask if a structural engineer has reviewed the plans. - What if I already see cracks in my concrete?

Small surface cracks are normal as concrete dries. But larger, deeper cracks could be a sign of poor design or installation. Consult a professional to inspect it. - Is reinforced concrete waterproof?

Concrete resists water to some extent, but it’s not completely waterproof. Special additives, coatings, or waterproofing techniques may be needed in basements or wet areas.

Glossary of Terms

Easy Definitions of Key Words

- Concrete: A mix of cement, sand, gravel, and water that hardens into a strong building material.

- Reinforced Concrete: Concrete that contains steel bars (rebar) to make it stronger and more flexible.

- Rebar: Steel rods placed inside concrete to resist tension (pulling and bending forces).

- Load: The weight or force that a structure must support.

- Compression: A force that pushes down or squeezes something.

- Tension: A force that pulls or stretches something.

- Water-Cement Ratio: The amount of water compared to cement in a concrete mix — affects strength and durability.

- Concrete Grade: A label (like M20 or C30) showing how strong the concrete is after it hardens.

- Slab: A flat layer of concrete used for floors or pavements.

- Beam: A horizontal structural element that supports weight, often reinforced with steel.

Conclusion

The Value of Getting the Math Right

Concrete may look simple, but behind every strong structure is careful planning, accurate math, and smart design. Whether it’s calculating the right thickness, choosing the correct concrete grade, or placing steel in the right spot — getting the math right means safer, longer-lasting buildings.

Even small mistakes in measurements or mix ratios can lead to cracking, sagging, or even structural failure. That’s why a solid understanding of reinforced concrete design — even at a basic level — can make you a more informed and confident homeowner, client, or builder.

When to Trust a Professional

While it’s great to understand the basics, large or load-bearing structures should always be reviewed and approved by qualified engineers or experienced contractors. They use advanced tools and knowledge to ensure your project meets safety standards and performs well over time.

References

- Design of Concrete Structures – Nilson, Darwin, Dolan – 2010 – McGraw-Hill Education

- Reinforced Concrete: Mechanics and Design – MacGregor, Wight – 2012 – Pearson Education

- Reinforced Concrete Design – Wang, Salmon – 1991 – HarperCollins College Publishers

- Concrete Technology – Neville, Brooks – 2010 – Pearson Education Limited

- Concrete: Microstructure, Properties, and Materials – Mehta, Monteiro – 2014 – McGraw-Hill Education

- Calculating Construction Equipment Utilization

- The Mathematics of Construction Materials Testing

- Calculating HVAC Requirements for Construction Projects

- The Future of Construction: AI-driven Calculations and Estimation

- Mastering Construction Measurement: Tools and Techniques

- Calculating Earthwork Volumes in Construction Projects

- The Role of Construction Calculations in Risk Management

- Estimating Concrete Quantities for Construction: Best Approaches

- Construction Calculations: Meeting Building Codes and Standards

- Financial Planning for Construction Projects: Advanced Calculations

- Calculating Strength of Construction Materials | Construction Insights

- Construction Cost Index: Significance, Calculation, and Trends

- Enhancing Construction Accuracy with BIM: Precise Calculations

- Construction Time & Cost Calculations: Techniques & Formulas

- Roofing Project Calculations: Essential Formulas

- Green Building Construction Calculations: Formulas for Sustainability

- The Mathematics of Reinforced Concrete Design in Construction

- Streamlining Construction Quantity Surveying: Tips for Efficient Cost Control

- Avoiding Costly Mistakes in Construction Calculations: A Comprehensive Guide

- Calculating Construction Labor Costs: Tips for Project Managers

- Efficiently Handling Construction Takeoffs: Best Practices

- The Importance of Accurate Construction Area Calculations | Key Factors & Benefits

- Construction Measurement Units Demystified: Metric vs. Imperial

- Top Construction Calculation & Estimation Software - Boost Efficiency!

- The Ultimate Guide to Construction Calculations: A Comprehensive Overview

- Optimizing Construction Project Budgets: A Data-Driven Approach

- Simplified Construction Estimation: Tips for Accurate Calculations

- Mastering Construction Math: 15 Fundamental Calculations Explained

- How to Calculate Material Quantities for Construction Projects

- Construction Cost Calculations: A Comprehensive Step-by-Step Guide