Construction Measurement Units Demystified: Metric vs. Imperial

Why Do Measurement Systems Matter in Construction?

Measurement systems play a crucial role in construction as they determine accuracy, efficiency, and consistency in project execution. The choice of measurement units impacts material estimation, structural integrity, and seamless collaboration between architects, engineers, and workers. Errors in measurement conversions can lead to costly mistakes, delays, and safety risks.

Understanding the two primary measurement systems—Metric and Imperial—helps construction professionals work effectively across different regions and international projects.

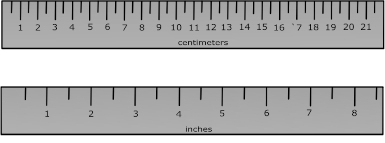

Overview of Metric and Imperial Systems

The two most commonly used measurement systems in construction are:

Metric System

- Based on units of ten for easy conversion.

- Uses meters (m), centimeters (cm), millimeters (mm) for length.

- Widely used in most countries, including Europe, Asia, and Africa.

Imperial System

- Uses inches, feet, and yards for length measurements.

- Commonly used in the United States and a few other countries.

- Conversions between units require specific multiplication or division factors.

Both systems have their advantages and are preferred based on regional practices and historical usage. Understanding the key differences helps professionals adapt and prevent measurement-related errors in construction projects.

Understanding the Metric System

Key Units Used in Construction

The metric system is based on units of ten, making conversions simple and efficient. The primary units used in construction include:

- Meter (m): The fundamental unit of length, used for large-scale measurements like room dimensions and building heights.

- Centimeter (cm): Commonly used for smaller structural components, furniture dimensions, and interior measurements.

- Millimeter (mm): Used for precise measurements in detailed construction work, such as gaps, fittings, and tolerances.

- Square Meter (m²): Used for measuring area, such as floor space and wall surfaces.

- Cubic Meter (m³): Used for measuring volume, such as concrete, soil, and water.

How the Metric System Works (Meters, Centimeters, Millimeters)

The metric system is based on a decimal structure, meaning units are scaled by factors of ten. This makes conversions straightforward:

- 1 meter (m) = 100 centimeters (cm)

- 1 centimeter (cm) = 10 millimeters (mm)

- 1 meter (m) = 1,000 millimeters (mm)

For larger measurements, the system extends to kilometers (km), where:

- 1 kilometer (km) = 1,000 meters (m)

Since all conversions follow a simple base-10 rule, calculations are easier compared to other measurement systems.

Advantages of the Metric System

The metric system offers several advantages, making it widely preferred in construction:

- Easy Conversions: Simple multiplication or division by powers of ten eliminates complex calculations.

- Universal Standard: Used in most countries worldwide, facilitating international collaboration.

- Greater Accuracy: Smaller units like millimeters allow for precise measurements, reducing errors.

- Efficiency in Design: Architects and engineers can create standardized designs that align with global standards.

- Consistency Across Disciplines: Used in engineering, architecture, and manufacturing, ensuring seamless coordination.

Overall, the metric system simplifies construction processes, improves accuracy, and minimizes conversion-related mistakes.

Understanding the Imperial System

Key Units Used in Construction

The Imperial system is primarily used in the United States and a few other countries. It is based on units that do not follow a decimal structure, making conversions more complex. The main units used in construction include:

- Inch (in): The smallest commonly used unit, often applied for detailed measurements like trim work and small components.

- Foot (ft): The fundamental unit for measuring lengths and dimensions in construction, equal to 12 inches.

- Yard (yd): Used for measuring larger areas, such as land plots and fencing; 1 yard equals 3 feet.

- Square Foot (ft²): Used to measure area, including flooring, walls, and land space.

- Cubic Foot (ft³): Used to measure volume, such as concrete, wood, and storage spaces.

How the Imperial System Works (Feet, Inches, Yards)

The Imperial system relies on units with varying conversion factors. Some key relationships include:

- 1 foot (ft) = 12 inches (in)

- 1 yard (yd) = 3 feet (ft) = 36 inches (in)

- 1 mile (mi) = 5,280 feet (ft)

For area and volume calculations:

- 1 square yard (yd²) = 9 square feet (ft²)

- 1 cubic yard (yd³) = 27 cubic feet (ft³)

Unlike the metric system, the Imperial system requires memorizing different conversion factors, which can sometimes lead to errors in calculations.

Advantages of the Imperial System

Despite its complexity, the Imperial system offers certain benefits, especially in construction:

- Familiarity in the U.S.: Widely used in American construction projects, making it essential for local builders and contractors.

- Practical for Construction Trades: Many materials, such as lumber and pipes, are manufactured in Imperial dimensions.

- Commonly Used in Legacy Projects: Many older buildings and infrastructure projects use Imperial units, requiring continuity in measurement systems.

- Works Well for Fractional Measurements: Inches are often divided into fractions (e.g., 1/2, 1/4, 1/8), making precise manual measurements easier.

While the Imperial system is less standardized globally, it remains an essential measurement system for many construction professionals in the U.S. and some other regions.

Key Differences Between Metric and Imperial Systems

Unit Conversion Challenges

One of the biggest differences between the Metric and Imperial systems is how conversions are handled. The Metric system is based on powers of ten, making it easy to convert between units. In contrast, the Imperial system uses inconsistent conversion factors, which can lead to confusion.

- Metric: Simple conversions (e.g., 1 meter = 100 centimeters, 1 kilogram = 1,000 grams).

- Imperial: Complex conversions (e.g., 1 foot = 12 inches, 1 yard = 3 feet, 1 mile = 5,280 feet).

In international construction projects, measurement conversions between the two systems can lead to costly errors if not done correctly.

Precision and Accuracy in Measurements

The Metric system is often considered more precise because it allows for finer increments using millimeters. The Imperial system, while practical for construction, relies on fractions of an inch, which can sometimes lead to rounding errors.

- Metric: Uses decimals for exact measurements (e.g., 2.75 meters).

- Imperial: Uses fractions (e.g., 2 feet 8 3/4 inches), which may require rounding.

In technical fields like engineering and architecture, metric measurements often provide greater accuracy and consistency.

Ease of Use in Construction

Construction professionals often find one system easier to work with based on their location and experience.

- Metric: Easier for calculations due to its decimal-based structure.

- Imperial: Familiarity in the U.S. and built into traditional construction practices.

While the Metric system is globally accepted, the Imperial system remains dominant in certain regions, making it necessary for professionals to understand both.

How to Convert Between Metric and Imperial Units

Common Conversion Formulas

Converting between Metric and Imperial units requires knowing key formulas. Below are some common conversions used in construction:

Length Conversions

- 1 inch = 25.4 millimeters (mm)

- 1 foot = 0.3048 meters (m)

- 1 yard = 0.9144 meters (m)

- 1 mile = 1.609 kilometers (km)

- 1 millimeter (mm) = 0.03937 inches

- 1 meter (m) = 3.2808 feet

- 1 kilometer (km) = 0.6214 miles

Area Conversions

- 1 square foot (ft²) = 0.0929 square meters (m²)

- 1 square yard (yd²) = 0.836 square meters (m²)

- 1 square meter (m²) = 10.764 square feet (ft²)

Volume Conversions

- 1 cubic foot (ft³) = 0.0283 cubic meters (m³)

- 1 cubic yard (yd³) = 0.7646 cubic meters (m³)

- 1 cubic meter (m³) = 35.3147 cubic feet (ft³)

Simple Tricks for Quick Conversions

For quick estimates in the field, use these simple tricks:

- Feet to Meters: Divide by 3 for a rough estimate (e.g., 10 feet ≈ 3 meters).

- Inches to Centimeters: Multiply by 2.5 (e.g., 12 inches ≈ 30 cm).

- Meters to Feet: Multiply by 3.3 (e.g., 5 meters ≈ 16.5 feet).

- Square Feet to Square Meters: Divide by 10 (e.g., 100 ft² ≈ 10 m²).

- Cubic Feet to Cubic Meters: Divide by 35 (e.g., 70 ft³ ≈ 2 m³).

Online Tools and Calculators

For precise conversions, professionals often use online calculators and mobile apps. Some popular options include:

- Google Unit Converter: Simply type conversions directly into Google.

- Construction Apps: Many construction apps offer built-in conversion tools.

- Online Calculators: Websites dedicated to metric-imperial conversions.

Using these tools ensures accuracy and saves time, especially in complex calculations.

Which System is Used Where?

Countries Using the Metric System

The Metric system is the most widely used measurement system worldwide. It is the official system in over 95% of countries, including:

- Europe: France, Germany, Italy, Spain, United Kingdom (officially, but Imperial is still used in some cases).

- Asia: China, Japan, India, South Korea.

- Africa: South Africa, Egypt, Nigeria.

- Australia & New Zealand: Fully metric.

- South America: Brazil, Argentina, Chile.

- Canada: Officially metric, but Imperial is still used in some industries (e.g., construction and real estate).

The widespread use of the Metric system is due to its simplicity, making calculations and conversions easier, especially in international projects.

Countries Using the Imperial System

The Imperial system is used in a few countries, with the United States being the primary user. However, Imperial units are also commonly used in:

- United States: The only major country where Imperial is the standard for construction, real estate, and road measurements.

- United Kingdom: Officially metric, but Imperial units are still used in construction, especially for height (feet/inches) and road distances (miles).

- Canada: While officially metric, construction and real estate often use feet, inches, and square feet.

- Myanmar & Liberia: These countries historically used Imperial but are transitioning towards metric.

In the U.S., construction materials, blueprints, and legal standards are primarily based on Imperial measurements, making it essential for professionals to understand this system.

Global Construction Standards

Since construction often involves international collaboration, many global standards accommodate both Metric and Imperial units. Some key global organizations and standards include:

- ISO (International Organization for Standardization): Uses metric as the default system for international standards.

- ASTM (American Society for Testing and Materials): Primarily uses Imperial but provides metric equivalents.

- BSI (British Standards Institution): Uses both Metric and Imperial, depending on the industry.

- IEC (International Electrotechnical Commission): Uses metric for electrical and engineering measurements.

Many modern construction companies and projects now provide dual measurements to ensure compatibility between Metric and Imperial users.

Choosing the Right System for Your Project

When to Use Metric vs. Imperial

The choice between Metric and Imperial systems depends on the project's location, industry standards, and the tools available. Here are some general guidelines:

- Use the Metric System:

- For projects in countries where Metric is the official system (e.g., Europe, Asia, Australia).

- When working with international teams and suppliers.

- For scientific, engineering, and precision-based work.

- Use the Imperial System:

- For projects in the United States, where Imperial is the standard.

- When dealing with traditional construction materials measured in feet and inches.

- For renovations and extensions of existing structures built using Imperial measurements.

Choosing the correct system from the start ensures consistency and prevents costly rework.

Adapting to International Construction Projects

When working on international projects, construction professionals may need to adapt to both measurement systems. Here’s how to ensure a smooth transition:

- Use Dual Measurements: Provide both Metric and Imperial values on blueprints and plans.

- Verify Supplier Standards: Confirm whether materials and tools are available in the required measurement system.

- Train Your Team: Ensure workers understand both systems and provide conversion charts on-site.

- Use Digital Tools: Leverage construction software that allows seamless conversions between Metric and Imperial units.

Avoiding Measurement Mistakes

Measurement errors can cause serious issues, including wasted materials, incorrect installations, and structural failures. Here are some tips to prevent mistakes:

- Always Double-Check Conversions: Small conversion errors can lead to significant miscalculations.

- Standardize Measurement Units: Ensure the entire project team is using the same system to avoid inconsistencies.

- Label Units Clearly: Mark all dimensions with the correct unit (e.g., "m" for meters, "ft" for feet).

- Use Precision Tools: Employ high-quality measuring instruments to minimize errors.

- Verify Before Cutting: When working with materials, measure twice and cut once to prevent waste.

By carefully selecting the appropriate measurement system and following best practices, construction professionals can enhance efficiency, reduce errors, and ensure project success.

Conclusion

Understanding the differences between the Metric and Imperial measurement systems is essential for construction professionals, as each system has its own advantages and challenges. The Metric system is widely used worldwide due to its simplicity and ease of conversion, while the Imperial system remains dominant in the United States and a few other regions.

For international projects, being familiar with both systems helps prevent costly errors, ensures smooth collaboration, and improves overall efficiency. Using accurate conversion methods, digital tools, and standardized measurements can minimize mistakes and streamline construction workflows.

Ultimately, choosing the right measurement system depends on project requirements, location, and industry standards. Whether using Metric, Imperial, or both, maintaining precision and consistency in measurements is key to successful construction planning and execution.

By adopting best practices and staying informed about global construction standards, professionals can adapt to any project environment and work effectively across different regions.

FAQs

1. Why do we use different measurement systems in construction?

Different countries and regions have historically adopted different measurement systems. The Metric system is widely used internationally due to its simplicity and ease of conversion, while the Imperial system remains common in the United States and a few other countries. Understanding both systems is essential for global construction projects and cross-border collaboration.

2. Can I use the Metric system in countries that use Imperial?

Yes, it is possible to use the Metric system in countries that primarily use Imperial units. However, it is important to provide dual measurements (Metric and Imperial) on plans and designs to avoid confusion. In regions like the United States, some construction sectors may still prefer Imperial units, so it's essential to communicate clearly with contractors and suppliers.

3. How do I convert between Metric and Imperial units easily?

For quick conversions, you can use simple tricks such as dividing feet by 3 to get meters or multiplying inches by 2.5 to convert them to centimeters. However, for accurate conversions, it's recommended to use proper formulas or online conversion tools to avoid mistakes in measurements.

4. Which system should I use for my construction project?

The choice between Metric and Imperial depends on your project's location and the standard used in your region. If you're working internationally or in countries where the Metric system is standard, it's best to use Metric. For projects in the U.S. or regions that follow Imperial measurements, you'll need to use the Imperial system or provide dual measurements to ensure compatibility.

5. Can I use both Metric and Imperial units in the same project?

Yes, it’s common to use both systems in international projects. To avoid confusion, always provide both Metric and Imperial measurements on blueprints, plans, and construction documents. This practice ensures that all teams involved are on the same page, especially when collaborating across different regions.

6. Where can I find tools to help with unit conversions?

There are various online tools and mobile apps that can help with unit conversions. Websites like Google’s Unit Converter and construction-specific apps provide accurate conversions between Metric and Imperial units. These tools save time and reduce the risk of manual conversion errors on the job site.

References

- Construction Mathematics – Surinder Virdi, Roy Tilley – 2010 – Pearson Education

- Metric Handbook: Planning and Design Data – Pamela Buxton – 2015 – Routledge

- Fundamentals of Building Construction: Materials and Methods – Edward Allen, Joseph Iano – 2013 – Wiley

- Basic Construction Materials – Theodore W. Marotta, Charles A. Herubin – 2005 – Pearson/Prentice Hall

- Building Construction Illustrated – Francis D. K. Ching – 2014 – Wiley

- Measurement Systems: Application and Design – Ernest O. Doebelin – 2003 – McGraw-Hill

- Engineering Drawing and Design – David A. Madsen, David P. Madsen – 2012 – Cengage Learning

- Practical Handbook of Material Flow Analysis – Paul H. Brunner, Helmut Rechberger – 2004 – CRC Press

- Calculating Construction Equipment Utilization

- The Mathematics of Construction Materials Testing

- Calculating HVAC Requirements for Construction Projects

- The Future of Construction: AI-driven Calculations and Estimation

- Mastering Construction Measurement: Tools and Techniques

- Calculating Earthwork Volumes in Construction Projects

- The Role of Construction Calculations in Risk Management

- Estimating Concrete Quantities for Construction: Best Approaches

- Construction Calculations: Meeting Building Codes and Standards

- Financial Planning for Construction Projects: Advanced Calculations

- Calculating Strength of Construction Materials | Construction Insights

- Construction Cost Index: Significance, Calculation, and Trends

- Enhancing Construction Accuracy with BIM: Precise Calculations

- Construction Time & Cost Calculations: Techniques & Formulas

- Roofing Project Calculations: Essential Formulas

- Green Building Construction Calculations: Formulas for Sustainability

- The Mathematics of Reinforced Concrete Design in Construction

- Streamlining Construction Quantity Surveying: Tips for Efficient Cost Control

- Avoiding Costly Mistakes in Construction Calculations: A Comprehensive Guide

- Calculating Construction Labor Costs: Tips for Project Managers

- Efficiently Handling Construction Takeoffs: Best Practices

- The Importance of Accurate Construction Area Calculations | Key Factors & Benefits

- Construction Measurement Units Demystified: Metric vs. Imperial

- Top Construction Calculation & Estimation Software - Boost Efficiency!

- The Ultimate Guide to Construction Calculations: A Comprehensive Overview

- Optimizing Construction Project Budgets: A Data-Driven Approach

- Simplified Construction Estimation: Tips for Accurate Calculations

- Mastering Construction Math: 15 Fundamental Calculations Explained

- How to Calculate Material Quantities for Construction Projects

- Construction Cost Calculations: A Comprehensive Step-by-Step Guide