Estimating Concrete Quantities for Construction: Best Approaches

Importance of Estimating Concrete Quantities

Estimating concrete quantities is a fundamental part of construction project planning and execution. The primary purpose of accurately estimating the amount of concrete required is to prevent both material wastage and shortages. Overestimating the amount of concrete can lead to unnecessary costs, including storage fees and disposal of excess material, while underestimating it can cause delays and force contractors to rush procurements, potentially affecting the overall timeline and project costs.

Additionally, accurate concrete quantity estimation is essential for project budgeting. It helps contractors and project managers determine the exact material costs, which in turn supports accurate budget forecasts. This enables clients and stakeholders to make informed decisions about the feasibility of a project and ensure financial resources are allocated efficiently.

Estimation also plays a key role in logistics and site management. By having a clear understanding of the required amount of concrete, construction teams can plan deliveries and schedule workers more effectively. Proper estimation helps avoid situations where trucks arrive with too much or too little concrete, both of which can disrupt construction workflows and lead to costly delays.

From a safety perspective, proper concrete quantity estimation ensures that the construction adheres to structural specifications. Concrete is used to form the foundation and critical load-bearing structures of a building, so ensuring that the right amount is mixed and poured according to design requirements is crucial for meeting safety standards and maintaining the integrity of the project.

Overview of Concrete in Construction Projects

Concrete is one of the most widely used building materials in the world, and its use spans a variety of construction projects, from residential homes to large infrastructure projects such as bridges, roads, and dams. The versatility of concrete comes from its ability to be molded into virtually any shape or size while maintaining strength and durability once it hardens. Concrete’s composition typically includes cement, water, aggregates (like sand and gravel), and often, additives for enhancing specific properties, such as strength, workability, or resistance to weather conditions.

Concrete is used for various structural and non-structural applications in construction. In residential and commercial buildings, it forms the foundation, walls, slabs, beams, and columns. For large infrastructure projects, it is used in the construction of highways, bridges, tunnels, and dams. The material’s flexibility allows it to be tailored to meet specific project needs, such as providing the required compressive strength or ensuring resistance to environmental factors like extreme temperatures and moisture.

The importance of concrete in construction cannot be overstated, as it serves as the backbone of most modern buildings and structures. Its strength, durability, and ability to withstand heavy loads make it a vital material for ensuring the safety and longevity of buildings. Additionally, concrete is highly resistant to fire, water, and many other environmental hazards, which makes it particularly suitable for high-risk construction areas. Furthermore, concrete’s sustainable properties, when mixed and used efficiently, make it a green building material, contributing to environmental goals in modern construction projects.

Given its widespread use and critical role in construction, proper planning, and estimation of concrete quantities are indispensable to the success of any project. Not only does it ensure the proper amount of materials are available, but it also plays a key part in controlling costs, maintaining safety standards, and ensuring the project is completed within its intended timeline.

Types of Concrete Used in Construction

Ready-Mix Concrete

Ready-mix concrete is a type of concrete that is manufactured in a batching plant, according to a set recipe or mix design, and then transported to the construction site in a ready-to-pour form. This type of concrete is typically used in large construction projects where consistent quality is important, and there is a need for large quantities of concrete to be delivered in a timely manner. Ready-mix concrete eliminates the need for on-site mixing, which saves time and labor costs, while also ensuring that the concrete has the exact properties required for the project.

One of the key advantages of ready-mix concrete is its ability to maintain uniformity in quality, as it is produced under controlled conditions in a factory. The concrete is also mixed and transported in specialized trucks, ensuring that it remains fresh and workable by the time it reaches the site. This reduces the risk of uneven mixing or inconsistencies in the final product. Ready-mix concrete is often used for foundations, pavements, floors, and other structural elements where precise quality and large quantities are needed.

Precast Concrete

Precast concrete refers to concrete components that are cast and cured in a controlled environment, typically in a factory setting, before being transported to the construction site. These components can include beams, walls, columns, slabs, and other structural elements. Precast concrete is often used in projects that require repetitive or standardized parts, such as apartment buildings, bridges, or industrial facilities.

One of the primary advantages of precast concrete is the ability to produce high-quality concrete elements under controlled conditions, free from weather-related delays or variables. This allows for faster construction since the precast elements are produced simultaneously with site preparation, meaning they can be installed quickly once the site is ready. Precast concrete also offers better quality control, as the materials are mixed and cast in a factory, ensuring uniformity and reduced risk of defects. Precast concrete elements can also be designed with specific features, such as insulation or aesthetic finishes, to suit the project's needs.

Site-Mixed Concrete

Site-mixed concrete, as the name suggests, is mixed on-site using a combination of cement, water, and aggregates. This type of concrete is commonly used for smaller projects or in situations where ready-mix or precast concrete is not feasible. The mixing process for site-mixed concrete can be done manually or with the help of a mixer machine, depending on the scale and nature of the project.

One of the main advantages of site-mixed concrete is its flexibility. It allows the concrete to be mixed according to the specific requirements of the project, which is particularly useful for custom or unique designs. However, this method requires a higher level of skill and attention to detail from the workers to ensure the correct proportions of materials are used. Site-mixed concrete is often used in small residential projects, foundations, or repairs, where large quantities of concrete are not necessary, or where site-specific conditions, such as access or timing, make other types of concrete unsuitable.

Methods for Estimating Concrete Quantities

Manual Calculation Methods

Manual calculation methods for estimating concrete quantities involve using simple mathematical formulas and measurements to determine the amount of concrete required for a given construction project. These methods are often employed in smaller projects or when a quick estimation is needed without relying on software tools.

The basic process involves measuring the dimensions of the area to be filled with concrete, such as the length, width, and depth of a slab, or the height, width, and length of a column or beam. Once these dimensions are known, the volume of concrete can be calculated by multiplying the length, width, and depth (or any other suitable formula for irregular shapes) to obtain the volume in cubic meters or cubic feet.

For example, to calculate the concrete needed for a slab, the formula is:

Concrete Volume = Length x Width x Depth

This method requires precision in measurements, and it’s important to consider factors such as reinforcement, formwork, and wastage to make the estimate as accurate as possible. Although it’s simple, this method can be time-consuming for large projects with complex geometries.

Using Software for Estimating Concrete Quantities

For larger or more complex projects, software tools provide a more efficient and accurate way to estimate concrete quantities. These programs are designed to handle intricate calculations and can automatically adjust for variables like reinforcement, material waste, and varying shapes. Popular construction estimation software includes tools like ProEst, Buildertrend, and ConcreteCalc Pro, which allow users to input the project’s design specifications, and they automatically calculate the required amount of concrete.

One of the main benefits of using software is the speed and accuracy it offers. It eliminates manual errors and is much faster, especially for projects with multiple concrete elements or complex designs. Some software also offers features like 3D modeling, which can help visualize the construction and estimate concrete quantities more precisely based on the actual geometry of the structure.

Software tools often come with pre-built templates for common construction elements, such as slabs, foundations, or walls, allowing estimators to quickly select the relevant options and input the required dimensions. Many software solutions also allow for integration with other project management tools, making it easier to coordinate materials, workforce, and scheduling.

Comparison of Methods

When comparing manual calculation methods to software-based estimation, the choice often depends on the complexity and scale of the project, as well as the available resources. Below is a comparison of both methods:

| Criteria | Manual Calculation | Software Estimation |

|---|---|---|

| Accuracy | Depends on the accuracy of measurements and calculations; prone to human error | Highly accurate, minimizes human error, accounts for complex factors automatically |

| Time | Time-consuming, especially for large or complex projects | Fast, especially for larger projects with multiple concrete components |

| Complexity of Project | Simple for straightforward projects, but becomes cumbersome for intricate designs | Ideal for complex projects, handles irregular shapes and varying dimensions easily |

| Cost | Low cost; requires only basic tools like a calculator and measuring tape | Higher upfront cost for purchasing software, but can save money over time due to increased efficiency |

| Flexibility | Flexible in approach, but requires more effort for adjustments | Highly flexible, especially with customizable options for different project types |

Key Factors Influencing Concrete Quantity Estimates

Dimensions and Design of Structures

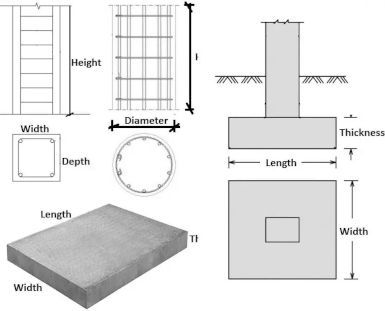

The dimensions and design of the structure are the most fundamental factors in estimating concrete quantities. The size and shape of the area to be poured directly influence the volume of concrete needed. The more complex the design, the more detailed the estimation process becomes. For example, estimating concrete for a simple rectangular slab is relatively straightforward, but for irregularly shaped foundations, or structures with curves, angles, and varying heights, calculations must be adjusted accordingly.

The type of structure—whether it is a slab, foundation, column, or beam—also dictates the amount of concrete required. Each structure has its unique characteristics, such as thickness or height, which must be factored into the calculations. In addition, the design of the structure, such as whether it's a single-layer or multi-layered slab, or whether the walls have different thicknesses at various sections, must be considered to determine the exact volume of concrete needed.

Type of Formwork

Formwork refers to the temporary or permanent molds into which the concrete is poured. The type of formwork used has a significant impact on the amount of concrete needed, as it determines the shape and size of the final concrete structure. If the formwork is intricate or includes complex shapes, it may require more concrete than simpler forms. Additionally, the materials used for formwork, such as wood, steel, or plastic, can influence the overall cost of the concrete estimate.

Moreover, the efficiency of the formwork system plays a crucial role in reducing or increasing the required concrete. Well-designed and properly executed formwork can prevent the waste of materials and ensure that the correct volume of concrete is placed into the right areas. It's important to consider both the size of the formwork and its design complexity when estimating the quantity of concrete.

Reinforcement and Embedded Items

Reinforcement, such as steel bars (rebar), mesh, or wire, is used in concrete to enhance its tensile strength. The amount of reinforcement required directly impacts the quantity of concrete needed, as space must be left around the reinforcement for the concrete to flow and properly encapsulate the material. For example, the placement of rebar in slabs, beams, or columns requires careful calculation of both the concrete needed to fill the formwork and the voids left around the reinforcement.

Embedded items like pipes, electrical conduits, and anchors also affect the concrete quantity estimate. These embedded elements create voids in the structure, which must be accounted for in the calculations. The more embedded items there are, the less concrete will be needed to fill the voids; however, the need to work around these elements can make the estimation process more complex and can require additional allowances for concrete to cover or encase these embedded items properly.

Waste Factors and Losses

Waste and losses are inevitable during the mixing, transportation, and pouring of concrete. Estimating these factors is essential for a more accurate concrete quantity calculation. Waste can result from spillage, over-mixing, excess material in the delivery trucks, or mishandling on the construction site. In addition, some concrete may be lost in the formwork, especially if it is not poured correctly or if there are defects in the formwork system.

Typically, a waste factor of around 5% to 10% is added to the initial estimate to account for these losses, though the actual percentage can vary depending on the type of project and the construction conditions. For instance, if the construction site is complex or if there are challenging access points for the concrete mixer trucks, the waste factor might need to be increased. Proper planning and efficient handling of materials can minimize waste, but it's still important to factor these elements into the overall estimate to avoid shortfalls.

Step-by-Step Guide for Estimating Concrete Quantities

Estimating Concrete for Slabs, Beams, and Columns

Estimating concrete for slabs, beams, and columns requires calculating the volume of each component based on its dimensions. Here's a step-by-step process:

- Measure the Dimensions: Begin by measuring the length, width, and depth (or thickness) of the slab, beam, or column. For slabs, measure the area (length x width) and the thickness. For beams and columns, measure the height, width, and depth.

- Apply the Formula for Volume: Use the formula for the volume of a rectangular prism (length x width x height). For slabs, it’s often a simple multiplication of length, width, and thickness. For beams and columns, measure the cross-sectional area and multiply by the length.

- Calculate the Concrete Volume: Multiply the dimensions for each part (slab, beam, or column) to obtain the volume of concrete required. For example, for a slab, you would calculate:

Concrete Volume = Length x Width x Thickness

- Account for Reinforcement: If there’s significant reinforcement (rebar or mesh), adjust the volume to account for the space around it. You may need to reduce the volume slightly, depending on the design.

- Add Waste Factor: Add a waste factor of 5-10% to account for spillage, variations in the mix, and losses during transportation and pouring.

Estimating Concrete for Foundations and Footings

Foundations and footings often require more detailed calculations due to their size and shape, which can vary depending on the soil conditions and the type of building. Here's how to estimate concrete for these components:

- Measure the Dimensions of the Footing: Measure the length, width, and depth of the footing. Footings can be rectangular, square, or even trapezoidal, so ensure to use the appropriate dimensions based on the shape.

- Calculate the Volume: For a rectangular or square footing, multiply the length, width, and depth to get the volume of concrete required:

Concrete Volume = Length x Width x Depth

- For Complex Shapes: If the footing has an irregular shape, break it down into smaller sections (rectangular or circular) and calculate the volume of each part separately, then sum the volumes.

- Consider the Base of the Foundation: The base of the foundation may have a different thickness than the rest of the footing. Make sure to account for this variation in depth when calculating the concrete volume.

- Add Reinforcement and Waste Factor: As with slabs, footings and foundations often have reinforcement. Calculate the space around rebar and include a waste factor (5-10%) for losses.

Estimating Concrete for Walls and Retaining Structures

Estimating concrete for walls and retaining structures requires careful measurement and calculation due to their size and height. Here's a method for estimating concrete for these elements:

- Measure the Dimensions: For walls, measure the height, length, and thickness. For retaining walls, the base width may vary, so it's important to measure both the height and the taper of the wall. Measure the length at the base and the top.

- Calculate the Volume for Straight Walls: For a straight wall, multiply the height, length, and thickness to get the volume:

Concrete Volume = Height x Length x Thickness

- Calculate the Volume for Retaining Walls: Retaining walls often have tapered sections. To estimate concrete for these, divide the wall into smaller sections (e.g., the base and the upper portion) and calculate the volume for each section, then sum the volumes.

- Include the Footing Volume: If the retaining wall has a footing or base slab, include this in your volume calculations. Measure the dimensions of the base and calculate the volume as you would for a foundation or footing.

- Account for Reinforcement and Waste: As with other components, account for reinforcement, especially if there are large amounts of rebar in the wall. Don't forget to add a waste factor for losses.

By following these steps, you can ensure that you estimate the right quantity of concrete for slabs, beams, columns, foundations, footings, walls, and retaining structures. This method helps prevent underestimation or overestimation, ensuring that the project stays on track in terms of both cost and time.

Tools and Equipment for Estimating Concrete Quantities

Concrete Volume Calculators

Concrete volume calculators are essential tools for estimating the amount of concrete required for various construction projects. These calculators can be found in both physical and online formats and are designed to quickly compute the volume of concrete based on the shape and dimensions of the structure being built. These tools are particularly useful for small to medium-sized projects and offer an easy, straightforward method for estimations.

Most concrete volume calculators require users to input basic measurements such as length, width, and depth (for rectangular or square structures) or the radius and height (for circular or cylindrical structures). Once the dimensions are provided, the calculator instantly calculates the required concrete volume in cubic meters or cubic yards. Many online calculators also have the option to add waste factors or account for reinforcement, making them more accurate for estimating the true material requirements.

These calculators are highly beneficial for construction professionals who need quick, simple, and accurate estimates for slabs, footings, or small-scale walls and columns. Some calculators also allow users to convert between different measurement units, making it easier to work with various systems of measurement (metric, imperial, etc.).

Estimation Software

Estimation software for concrete quantities is a more advanced tool designed to handle complex calculations, manage large-scale projects, and streamline the overall estimating process. Unlike manual methods or simple calculators, estimation software can handle intricate designs, including irregular shapes, complex geometries, and multi-level structures. These software solutions are often used by large construction companies or contractors working on high-budget, high-complexity projects.

Popular software for estimating concrete quantities includes programs like ProEst, Buildertrend, and ConcreteCalc Pro, which are capable of handling concrete volume calculations, cost estimates, project management, and material scheduling. These tools not only help determine the volume of concrete required but also account for factors such as waste, reinforcement, and other embedded items. Many software programs also include pre-set templates for common concrete structures (such as slabs, beams, foundations), which further simplifies the estimation process.

Estimation software offers the advantage of speed and accuracy, as calculations are done instantly and automatically based on the user’s input. It also helps minimize human error, ensures consistency in estimates, and allows for better project planning and material management. Additionally, many software programs offer cloud-based features, enabling teams to collaborate in real-time and access estimates from any location, making them ideal for large projects with multiple team members.

Mobile Apps for On-Site Estimation

Mobile apps for on-site estimation have become increasingly popular in the construction industry, providing contractors and estimators with the flexibility to calculate concrete quantities directly from the job site. These apps offer a user-friendly interface and can be installed on smartphones or tablets, allowing users to make estimates on the go, without needing a computer or physical calculator. Mobile apps are perfect for contractors who need quick, accurate calculations while working on-site, ensuring that concrete orders match the actual project requirements.

Most mobile apps for concrete estimation allow users to input project-specific details, such as measurements, reinforcement requirements, and waste factors, to calculate the precise amount of concrete needed. Popular apps like Concrete Estimator and iFormwork enable users to enter project dimensions and receive instant volume calculations, along with cost estimates and material requirements. Many of these apps also include features for generating reports, taking photos, and recording notes, which can help streamline communication between team members and clients.

One of the biggest advantages of using mobile apps is the convenience they offer. Construction professionals can access and update their estimates immediately, even in challenging on-site conditions, without needing to return to an office or desktop computer. This capability can significantly reduce the time required for material procurement and ensure that the project progresses on schedule.

In addition to basic volume calculations, some apps also provide advanced features such as project cost tracking, concrete delivery scheduling, and material inventory management. These added features help to manage costs and logistics more effectively, ensuring that the right amount of concrete is delivered at the right time to avoid delays and wastage.

Common Mistakes to Avoid in Estimating Concrete Quantities

Overestimating or Underestimating Material Needs

One of the most common mistakes in estimating concrete quantities is either overestimating or underestimating the amount of material needed. Overestimating can lead to unnecessary costs due to excess concrete, which may require additional storage, transportation, or disposal. On the other hand, underestimating the material requirements can result in delays and additional costs when more concrete needs to be ordered mid-project, or when insufficient concrete is available to complete the task.

To avoid this, it's crucial to measure dimensions as accurately as possible and consider the exact specifications of the project. It is also advisable to consult project blueprints or work closely with engineers and designers to ensure that the required amounts of concrete are estimated based on the most accurate design data. It's often a good practice to add a small margin of error (typically 5-10%) to account for unforeseen circumstances while keeping the estimate realistic and within budget.

Not Accounting for Waste and Losses

Another common mistake is failing to account for waste and losses during the mixing, transport, and pouring of concrete. Concrete may be lost due to spillage, over-mixing, or during the unloading process, especially if the project site has difficult access or weather-related challenges. It's also possible that some of the concrete will be lost in the formwork or be unusable due to improper handling.

Without factoring in these potential losses, the project could face shortages that cause delays or force the contractor to source more concrete on short notice. To prevent this, always include a waste factor in your estimates. Typically, a waste allowance of 5-10% is added, but this can vary based on project conditions. For larger or more complicated jobs, it may be wise to increase the waste factor to ensure that enough concrete is available to account for unavoidable losses.

Incorrect Measurement Units

Incorrect measurement units can lead to significant errors in concrete quantity estimation. Mixing up units like cubic meters (m³) and cubic feet (ft³), or failing to convert between metric and imperial systems, can result in substantial miscalculations. For example, mistakenly calculating in cubic meters when the project requires cubic yards, or vice versa, could result in a serious shortage or surplus of material.

To avoid such errors, always double-check the measurement units being used, especially when working with international teams or in different regions that may use different systems. Use a consistent system of measurement throughout the project (either metric or imperial) and ensure that all calculations are converted correctly. Using online conversion tools or unit conversion features in estimation software can help prevent these types of mistakes and ensure the proper amount of concrete is ordered.

Best Practices for Accurate Concrete Quantity Estimation

Double-Checking Measurements

Accurate measurements are the foundation of precise concrete quantity estimates. To avoid errors, always double-check all dimensions before proceeding with calculations. Even a small mistake in measuring the length, width, or depth can lead to significant discrepancies in the final concrete volume estimate. It's helpful to use reliable measuring tools such as tape measures, laser distance meters, or calibrated devices to ensure accuracy.

Additionally, it's a good practice to have measurements verified by a second person or to cross-check with project blueprints or drawings. For larger or more complex projects, consider measuring multiple times or from different reference points to ensure consistency across all parts of the structure. This extra step can prevent costly mistakes that arise from inaccurate measurements.

Accounting for Variations in Material Properties

Concrete can vary in properties such as moisture content, air content, and mix design, which can affect its volume and weight. For example, a mix that is too wet or too dry could yield slightly different quantities of concrete than initially estimated. Variations in aggregate size or moisture content in the sand and gravel used can also influence the final mix and its behavior during placement.

To account for these variations, it's important to use consistent and accurate mix designs, and when possible, work with concrete suppliers to ensure that the materials used are suitable for the project. Additionally, regularly check the moisture content of aggregates and adjust the mix if necessary. If working with specific concrete strengths or environmental conditions (such as extreme heat or cold), take these factors into account, as they can also affect the overall concrete requirements.

Involving Engineers and Designers in the Estimation Process

Collaborating with engineers and designers during the concrete estimation process is crucial for ensuring that all project specifications are met. Engineers can provide valuable insight into structural requirements, reinforcement needs, and the overall design of the building or structure, which can directly impact the quantity of concrete needed. By involving them early in the estimation process, you can ensure that the estimate aligns with the actual project requirements.

Designers can also help identify any unique project features that might require more concrete or special handling, such as intricate formwork or complex shapes. Having engineers and designers review the quantity estimate ensures that all relevant factors, including reinforcement, embedded items, and potential adjustments, are considered, leading to more accurate results.

Lastly, clear communication and collaboration with these experts can help prevent errors and ensure that the concrete is ordered correctly, reducing the risk of shortages, delays, or excess material. Regularly reviewing the project’s plans and estimates together with engineers and designers can help catch potential issues early in the process, ensuring smooth execution throughout the construction phase.

Conclusion

Accurately estimating concrete quantities is a vital aspect of any construction project, whether it's a small residential building or a large infrastructure project. The success of a project often depends on how well concrete quantities are calculated, as incorrect estimates can lead to cost overruns, delays, and material wastage. By following best practices such as double-checking measurements, accounting for material variations, and involving engineers and designers in the estimation process, contractors can ensure more precise and reliable estimates.

The methods available for estimating concrete quantities—ranging from manual calculations and software tools to mobile apps for on-site estimation—offer varying levels of efficiency and accuracy. Each method has its advantages, and the choice of method will depend on the size, complexity, and resources available for the project. Regardless of the method chosen, incorporating waste factors, reinforcement needs, and specific project conditions is essential to ensure that the estimation process reflects the true concrete requirements.

By carefully considering all the key factors that influence concrete estimation, such as dimensions, formwork, reinforcement, and potential losses, construction professionals can prevent common mistakes and improve the overall efficiency of their projects. Ultimately, accurate concrete quantity estimation not only helps control costs but also contributes to the safety, quality, and timely completion of the project.

FAQs

1. Why is accurate concrete quantity estimation important?

Accurate concrete quantity estimation is essential to prevent over-ordering or under-ordering concrete, both of which can lead to unnecessary costs, delays, or project interruptions. Proper estimation ensures that the required amount of concrete is available when needed, minimizing waste and optimizing the construction process.

2. How do I calculate the volume of concrete for a slab?

To calculate the volume of concrete for a slab, simply multiply the length, width, and thickness of the slab. The formula is:

Concrete Volume = Length x Width x ThicknessEnsure you use consistent units for all dimensions, and account for any waste or reinforcement in the final estimate.

3. What tools can I use to estimate concrete quantities?

There are several tools available to estimate concrete quantities, including:

- Concrete volume calculators (online or physical calculators)

- Estimation software (e.g., ProEst, Buildertrend)

- Mobile apps for on-site estimation (e.g., Concrete Estimator, iFormwork)

4. How do I account for waste when estimating concrete?

To account for waste, you should add a waste factor to your estimate. Typically, a waste factor of 5-10% is used, but it may vary depending on the complexity of the project, the weather conditions, and site accessibility. This helps ensure that you have enough material to cover any unexpected losses during mixing, transportation, or pouring.

5. Can I use manual calculations instead of estimation software?

Yes, manual calculations can be used for estimating concrete quantities, especially for smaller, simpler projects. However, for larger or more complex projects, estimation software can offer more accuracy, save time, and handle intricate design calculations more effectively. It also helps reduce human error and can integrate other project management aspects.

6. How do I estimate concrete for irregularly shaped structures?

For irregularly shaped structures, break the shape down into smaller, simpler sections, such as rectangles, squares, or circles. Calculate the volume for each part separately and then sum the volumes. If the shape is highly complex, it may be necessary to use estimation software or consult with engineers for a more accurate calculation.

7. Should I involve engineers in the concrete estimation process?

Yes, involving engineers and designers is highly recommended. They can provide detailed information about the structure, reinforcement requirements, and unique design features that may influence the concrete quantity. Their input helps ensure that the estimate aligns with the project's actual needs, minimizing errors and improving overall accuracy.

References

- Ralph, H. (2017). Concrete Construction Engineering Handbook. CRC Press.

- Turner, G. (2018). Estimating Building Costs for Dummies. Wiley.

- Concrete Society. (2020). Concrete Estimation Guidelines. The Concrete Society. Retrieved from https://www.concrete.org.uk/

- Smith, J. (2019). Practical Concrete Estimating. McGraw-Hill.

- Buildertrend. (2021). Construction Estimating Software. Retrieved from https://www.buildertrend.com/

- ProEst. (2021). Concrete Estimating Software. Retrieved from https://www.proest.com/

- American Concrete Institute. (2021). ACI Manual of Concrete Practice. American Concrete Institute. Retrieved from https://www.concrete.org/

- iFormwork. (2021). Concrete Estimating App. Retrieved from https://www.iformwork.com/

- Calculating Construction Equipment Utilization

- The Mathematics of Construction Materials Testing

- Calculating HVAC Requirements for Construction Projects

- The Future of Construction: AI-driven Calculations and Estimation

- Mastering Construction Measurement: Tools and Techniques

- Calculating Earthwork Volumes in Construction Projects

- The Role of Construction Calculations in Risk Management

- Estimating Concrete Quantities for Construction: Best Approaches

- Construction Calculations: Meeting Building Codes and Standards

- Financial Planning for Construction Projects: Advanced Calculations

- Calculating Strength of Construction Materials | Construction Insights

- Construction Cost Index: Significance, Calculation, and Trends

- Enhancing Construction Accuracy with BIM: Precise Calculations

- Construction Time & Cost Calculations: Techniques & Formulas

- Roofing Project Calculations: Essential Formulas

- Green Building Construction Calculations: Formulas for Sustainability

- The Mathematics of Reinforced Concrete Design in Construction

- Streamlining Construction Quantity Surveying: Tips for Efficient Cost Control

- Avoiding Costly Mistakes in Construction Calculations: A Comprehensive Guide

- Calculating Construction Labor Costs: Tips for Project Managers

- Efficiently Handling Construction Takeoffs: Best Practices

- The Importance of Accurate Construction Area Calculations | Key Factors & Benefits

- Construction Measurement Units Demystified: Metric vs. Imperial

- Top Construction Calculation & Estimation Software - Boost Efficiency!

- The Ultimate Guide to Construction Calculations: A Comprehensive Overview

- Optimizing Construction Project Budgets: A Data-Driven Approach

- Simplified Construction Estimation: Tips for Accurate Calculations

- Mastering Construction Math: 15 Fundamental Calculations Explained

- How to Calculate Material Quantities for Construction Projects

- Construction Cost Calculations: A Comprehensive Step-by-Step Guide